Lexan Margard sheets are a popular choice for a wide range of industrial and construction applications due to their high impact resistance, UV resistance, and chemical resistance.

These thermoplastic polycarbonate sheets are specially coated with a hard, scratch-resistant coating called Margard, which provides an additional layer of protection.

In this article, we will be discussing the various benefits of using Lexan Margard sheets. From protecting machines and buildings from sharp objects, liquids, and abrasive materials to reducing maintenance costs, the advantages of Lexan Margard sheets are numerous.

They are also suitable for different types of machines, are easy to handle and cut to the required length, and have a sealant edge that helps prevent liquids from penetrating into the building.

Here are the top 5 benefits of Lexan Margard sheets:

Table of Contents

1. High Impact Resistance

Lexan Margard sheets are highly resistant to impact and ideal for use in areas where machinery or equipment is in operation. This feature makes them suitable for harsh environments and can help prolong the life of machinery or equipment.

2. Chemical resistance

Lexan Margard sheets are resistant to a wide range of chemicals, making them suitable for use in harsh environments.

This feature makes them perfect for industrial and construction settings, as well as in medical and food processing environments. They can withstand exposure to various chemicals and substances, making them a durable and long-lasting choice for many applications.

3. UV resistance

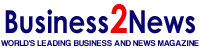

The additional UV-resistant coating on Lexan Margard sheets protects the plastic from yellowing and cracking caused by exposure to sunlight. This makes them suitable for use in outdoor applications, such as skylights, glazing, and more.

4. Easy to clean

Lexan Margard sheets are easy to clean and maintain, which makes them ideal for use in hygienic applications such as food processing and medical equipment, where cleanliness is important.

5. Easy to fabricate

Lexan Margard sheets can be easily cut, bent, and formed to fit a variety of applications, making them versatile and easy to work with in different projects. This feature makes them perfect for different types of applications and can be customized to fit specific requirements.

6. High optical quality

Lexan Margard sheets have a high level of optical clarity, which makes them suitable for use in a variety of visual applications such as glazing, machine guards, and skylights.

7. Cost-effective

Lexan Margard sheets are cost-effective and long-lasting when compared to other materials such as glass and metal, which makes them a good choice for cost-sensitive applications.

8. Temperature resistance

Lexan Margard sheets can withstand high temperatures without deforming or melting, which makes them suitable for use in areas where temperatures fluctuate, such as in high-heat machinery and equipment.

9. Lightweight

Lexan Margard sheets are lightweight, making them easy to handle and install, ideal for large-scale projects and frequent moving and handling. This feature can make the installation process more efficient and cost-effective. Additionally, their lightweight design also makes them easy to transport.

10. Flexible

Lexan Margard sheets are highly flexible and can be bent, shaped, and formed to fit a wide range of applications. Their versatility makes them suitable for many different projects, whether it’s industrial, construction, or visual applications.

Final words

Lexan Margard sheets offer many benefits, including high impact resistance, UV resistance, chemical resistance, temperature resistance, easy fabrication, and more.

They are suitable for various industries and applications, and easy to handle and install. The benefits of Lexan Margard sheets make them a reliable and durable choice for many projects.