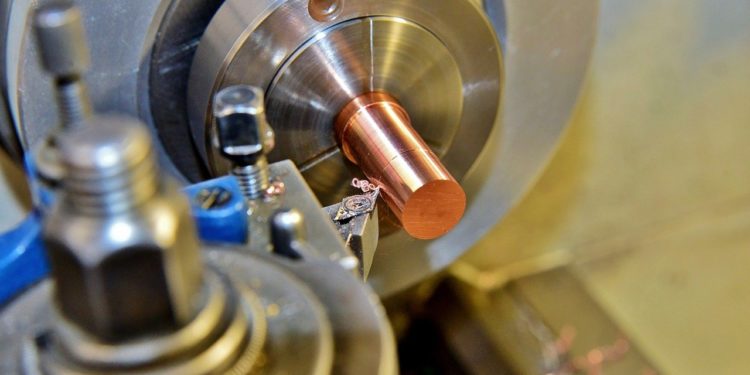

In a digitally-driven world, the term ‘automation’ in business means so much more than it ever used to. We are replacing more and more human labour with machines like cnc metal cutting, co2 laser cutting machine and coil automation equipment.

Automation leaves human workers with more time and energy to focus on other tasks that may add more value, or that simply cannot be taken over by machines. Think repetitive and monotonous tasks that are still incredibly important to the running of a business, but are a drain on worker’s time.

No matter the size of your business, if you deal with manufacturing processes, you should be considering what automation can do for you. But how can it benefit your business? Here are the three key areas that automation can transform in any manufacturing process.

Table of Contents

Safety

The first and incredibly important point to make is how automation can improve the safety within your workplace. Some manufacturing processes come with an element of safety risk. Manufacturers do not have a 9-5 desk job and it’s a job that has been somewhat infamous for being unsafe in the past.

Whilst things have definitely changed for the better, much of this is down to the rise in automation. It means that particularly dangerous and laborious tasks can be delegated to robots, reducing the likelihood of injuries in the workplace. It also means that tasks can be introduced that are beyond the scope of a human employee, such as lifting very heavy parts or a number of parts at a time. Automation with the help of CNC machining companies allows you to pick up the pace of your business with its precision manufacturing process.

Productivity

This leads to the next point; productivity. Whilst a human worker will tire and need breaks, machines don’t. They are the most productive employee you’ll ever invest in! Automation allows you to pick up the pace of your business and focus on moving forward.

Robots are taking on jobs that are proving difficult to fill manually, arguably as a result of the STEM skills shortage. Investing in hyper-productive automation can only be a good thing.

Accuracy

Not only is automation providing a safer, more productive environment, there is also less risk of error. Repetitive work can lend itself to errors when being carried out by human workers. Automation, however, adds an extra later of infallibility. The robot will always go back to where it is programmed to with pinpoint accuracy thanks to a multitude of different detection and monitoring software involved.

Increased accuracy leads to more uptime, fewer wasted materials and identical and precisely manufactured products. The job can be carried out with minimal manpower necessary.

Collaboration

Although automation has its place within a company and can take on certain tasks more effectively than a human worker, it does not render your employees redundant by any stretch. A lot of automation actually requires human intervention in order for them to perform. This is particularly true for collaborative robots, or cobots for short.

Cobots are designed to work alongside humans, whilst upskilling workforces and enabling employees to undertake more value-adding activities. Cobots are also accessible for many different businesses, of all different sizes. They cost less to purchase and maintain than their larger industrial counterparts and are safer to use and easier to deploy. They can be a real game-changer for small and medium-sized businesses that cannot afford to or do not need to invest in something more complex.

Automation in business, whether that be in manufacturing or other sectors, is only gaining momentum. Every business process is on the table for automation. It is changing the modern-day workplace for the better.